Direct reduced Iron(DRI)

Overview of the Direct Reduced Iron (DRI) Process

The Direct Reduced Iron (DRI) process is an alternative ironmaking method that reduces iron ore to metallic iron without melting. This is achieved by exposing iron ore pellets or lumps to a reducing gas—typically composed of hydrogen (H₂) and carbon monoxide (CO)—at temperatures between 800°C and 1,050°C. The resulting product, DRI or “sponge iron,” can be utilized directly in electric arc furnaces (EAFs) or further processed into hot briquetted iron (HBI) for ease of transport and storage.

Key Technologies:

- MIDREX: The most widely adopted DRI technology, accounting for over 80% of global shaft furnace DRI production.

- Energiron (HYL): A flexible process capable of utilizing natural gas, hydrogen, or a combination thereof.

- Rotary Kilns: Predominantly used in coal-based DRI production, especially in regions like India.

Energy Consumption and Emissions

The energy requirements and carbon emissions of DRI production vary based on the reducing agent used:

Natural Gas-Based DRI:

- Energy Consumption: Approximately 10.4 GJ per tonne of DRI, equivalent to about 2,890 kWh.

- CO₂ Emissions: Around 0.6 tonnes of CO₂ per tonne of DRI produced.

Coal-Based DRI:

- Energy Consumption: Typically higher, ranging between 4–5 Gcal per tonne of DRI (approximately 16.7–20.9 GJ).

- CO₂ Emissions: Higher due to the carbon-intensive nature of coal.

Hydrogen-Based DRI:

- Energy Consumption: Comparable to natural gas-based processes but can be optimized with renewable energy sources.

- CO₂ Emissions: Potentially near-zero when using green hydrogen produced from renewable energy.

Capital Costs of DRI Facilities

The capital expenditure (CapEx) for establishing a DRI facility varies based on capacity, technology, and location:

Natural Gas-Based DRI Plants:

Estimated CapEx: Approximately $263.5 per tonne of steel capacity.

Hydrogen-Based DRI Plants:

Estimated CapEx: Around $685 per tonne of steel capacity, reflecting the additional infrastructure for hydrogen production and handling.

Large-Scale Projects:

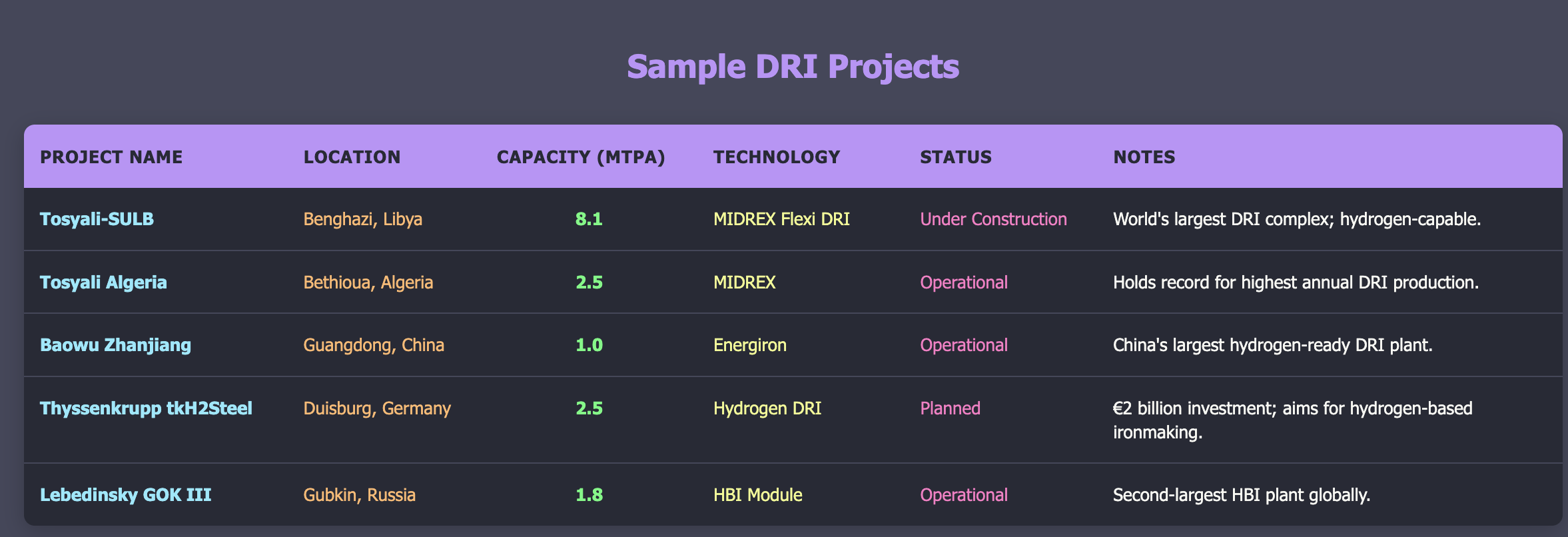

Example: Thyssenkrupp’s planned DRI plant in Germany, with a capacity of 2.5 million tonnes per annum, has an estimated investment of €2 billion.

Major Existing and Upcoming DRI Projects

Below is a table highlighting some of the largest existing and planned DRI facilities worldwide: Hydrogen-Based Direct Reduced Iron: Current Status and Economics. This list is far from exhaustive.

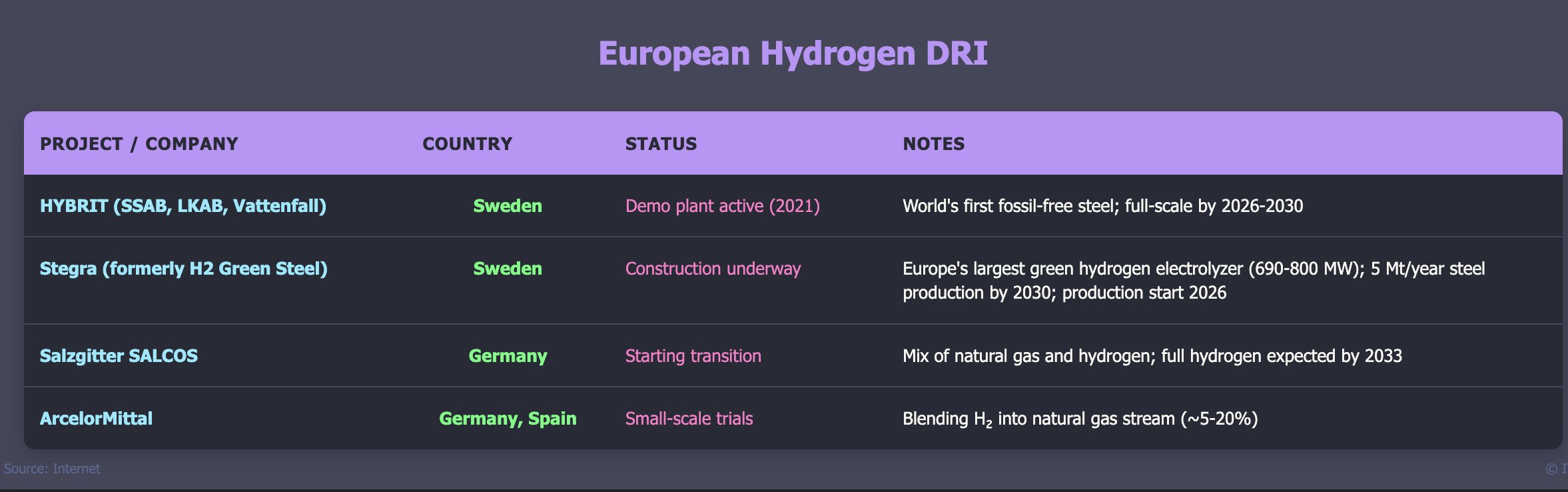

Hydrogen-based DRI represents an emerging decarbonization pathway that is not yet implemented at large commercial scale. Current developments include pilot projects and early commercial plants across multiple countries, with most operations remaining pre-commercial with capacity under 1 Mt per year.

Major Hydrogen DRI Projects

Stegra represents the most advanced hydrogen DRI project globally, featuring a fully integrated steel mill in Boden, northern Sweden, that will be Europe’s first new steel mill in 50 years. The facility includes a 690-800 MW electrolyzer powered by renewable electricity, making it Europe’s largest green hydrogen production plant. The project secured approximately €6.5 billion in funding and received €250 million from the EU Innovation Fund plus €100 million from the Swedish Energy Agency. EuropaStegra Construction began in 2022 with major equipment installations ongoing since 2024, targeting 5 million tonnes of annual green steel production with 95% lower carbon emissions compared to traditional blast furnace processes. STEGRA: welcoming a new era of green steel production - European Commission

Most current projects utilize natural gas as the primary reductant with hydrogen blending for demonstration purposes, though Stegra’s fully hydrogen-based approach represents a significant advancement toward commercial-scale implementation of the technology.