Logistics

This article draws very heavily on a piece by icecubed

I start with an extended quote:

Typically, a wind farm deploying 5 or 6 MW units will require the delivery of about 5,500 tonnes of materials per turbine, or 925 tonnes per MW of installed capacity. The internal access road network is typically in the range of 1.5km per turbine and is built to cater for mobile cranes operating on axle loads of up to 36 tonnes. Of these constituent materials, approximately 20% of the vehicle mass moved is turbine componentry. The remaining constituent materials are consumed or utilised during the construction of the balance of plant.

The balance of plant elements for a wind farm refers to the roads, footings, crane hardstands and electrical infrastructure needed to connect generating units to the power grid. Electrical infrastructure comprises approximately 10% of the freight task. The vast majority of this is the thermal bedding sand needed for underground cables. Pavement materials for the construction of roads and hardstands is the largest contributor to offsite road impacts at 35% of loads and the remaining 30% is associated with concrete and reinforcement for foundations. Construction water is the most significant variable, approximately 5% of the freight task is used for supply needed for the processing of earthworks, dust suppression and concrete production. Despite their significant size and weight, the primary impact on road infrastructure is not due to the transportation of turbine components. They only occupy a small proportion of the overall freight task.

So for 1000 MW about 1 million tonnes of materials.

Problem - Wind turbines are hard to move from port to site.

Modern 6 MW windturbines are over size and over weight (OSOW) arguably much like most of us. This presents significant logistical challenges.

Rotor & Blades

For example, the Vestas V150-6.0 MW has a rotor diameter of 150 m (i.e. each blade is about 75 m)

Other 6 MW / near-6 MW designs use rotor diameters in the range ~140–160 m (or sometimes slightly less, depending on site constraints or segmented blades)

So you might expect:

Blade length: ~70–80 m (for a 150 m rotor)

Blade weight: on the order of 20–40 t (depending on design)

Rotor hub / hub + blade assembly combined is also considerable mass (hub, bearings, root attachments, etc.)

Tower

The towers are usually tubular steel (or hybrid) sections, often delivered in segments (e.g. base, middle, top) because of transport constraints.

- The hub heights for 6 MW turbines are often in the range 100–160 m, depending on the design, site wind regime, and constraints. For instance, the V150-6.0 offers hub heights of 105 m, 125 m, 148 m, 155 m, 166 m (i.e. depending on site variant)

- The bottom (base) diameter of the tower can be quite large (several meters). Because of road transport constraints, towers larger than ~4–5 m diameter become difficult to move in one piece.

- Tower sections can be very heavy; individual sections (especially the base) may weigh tens to over 100+ tonnes each, depending on size and thickness. The entire tower (all sections) may weigh a few hundred tonnes or more in modern large turbines (for 5–6 MW scale)

NSW

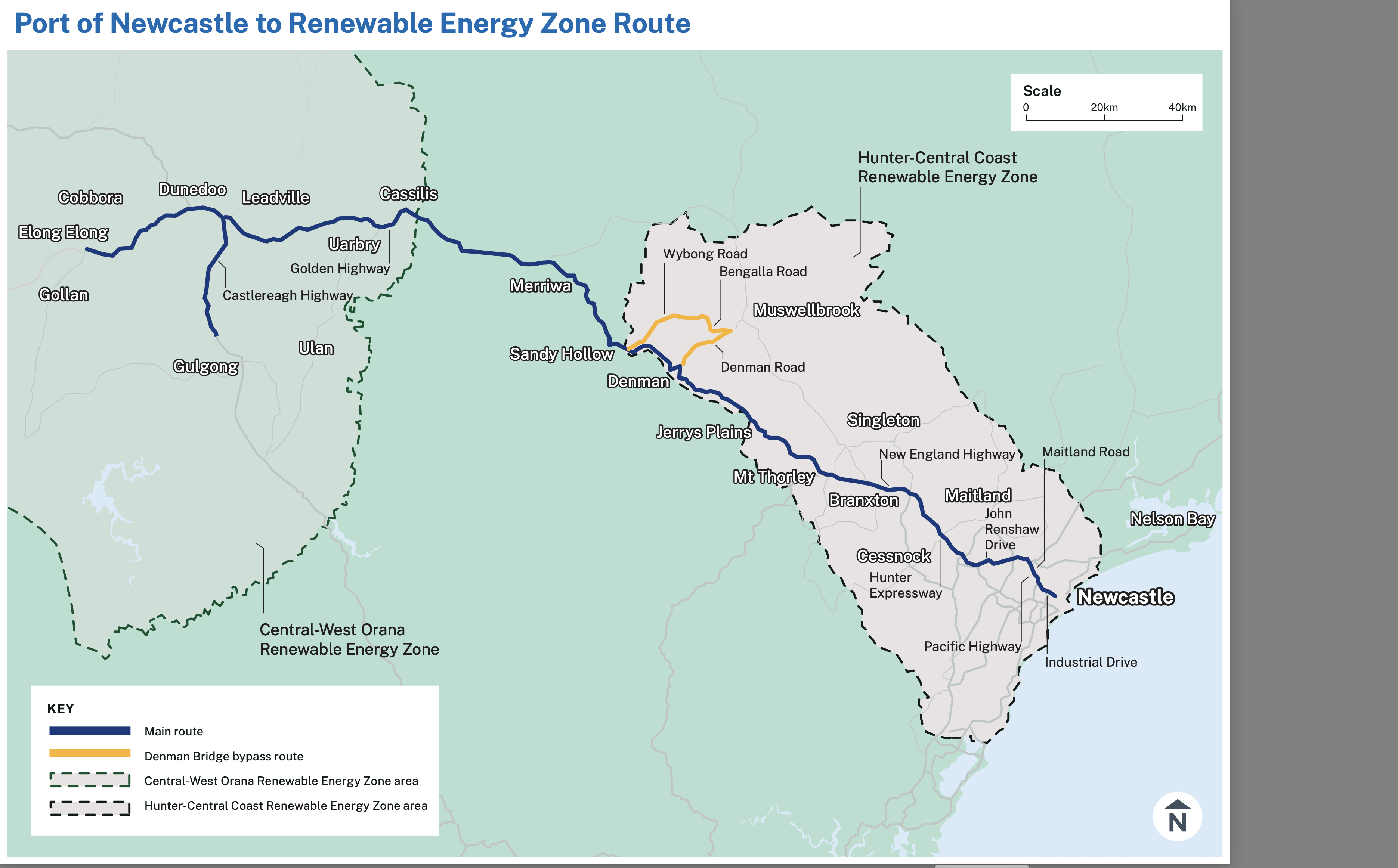

In NSW the State Goverment in its usual fashion has stepped in to address the issue and perhaps one of the first benefits of the Orana REZ is a coordinated route access from the port of Newcastle to the zone. This requires port, road and a bridge upgrade. However the Denman bridge upgrade is maybe not going to happen. Energyco states:

Our initial investigations show that Denman Bridge can support a majority of OSOM vehicle movements without upgrade. Some construction components will need to be transported around the bridge such as wind turbine base tower bodies and high voltage transformers. An alternative route using Denman Road, Bengalla Link Road and Wybong Road is currently being investigated.

Queensland

The main issue in Queensland different to every other State is the requirements for police escorts. And I have been told by various people that the Queensland police are essentially only available for 1 turbine per week. So that means that only about 300 MW of turbines can be delivered in Queensland per year and naturally escorts are pricey.

And in fact I believe the one time a turbine blade got stuck under a bridge was on the Warrego Highway near Ipswich in Queensland, police escort or no.

So this is a standard form of official racket, no different to any other union.

Without wanting to rant about it, on that basis it takes over 3 years to deliver the turbines for the Bungapan wind farm alone. In my view this is entirely unacceptable. It’s like the Goverment forcing the industry to be unproductive, thereby forcing costs up for consumers. Cut off the nose to spite the face.