Strengthening Gladstone transmission

Powerlink is proposing to spend about $2.5 bn to provide about 2 GW of new transmission to support the retirement of Gladstone Power station around 2030. For industrial decarbonisation nerds Gladstone is the No 1 target in Australia and could be a global model. But it’s just a dream that no decision maker takes seriously.

Background

Transmission is normally only of interest to anyone when people are fighting about it. I have long, long believed that once the transmission is built everyone will forget about it. Ten years ago most people would drive under a transmission line and wouldn’t think twice about it. E.g. Awareness test But when your awareness and consciousness are raised and it becomes an identity issue (for or against transmission) then all of a sudden it’s life and death. And I speak as someone that can see transmission out my window, and couldn’t give a rats, and I fly my model planes close to transmission lines and that is a live issue, so to speak.

If South Australia is one of the most interesting regions in the world as a, successful, proof of concept, for renewable grids then Gladstone is arguably the next most interesting. Not because it has much renewables yet but because it offers so much scope for integrated, heavy industry decarbonisation via electricity.

Gladstone’s potential has been written up nearly once a year by everyone from Federal Parliament to Climateworks. The most recent Climateworks report published in February was the result of a significant body of work, but like most reports will achieve nothing without buy in from the major stakeholders, that is the Queensland and Federal Govts and the industrial companies that operate there. Gladstone is a centre with unique potential but there is no change agent.

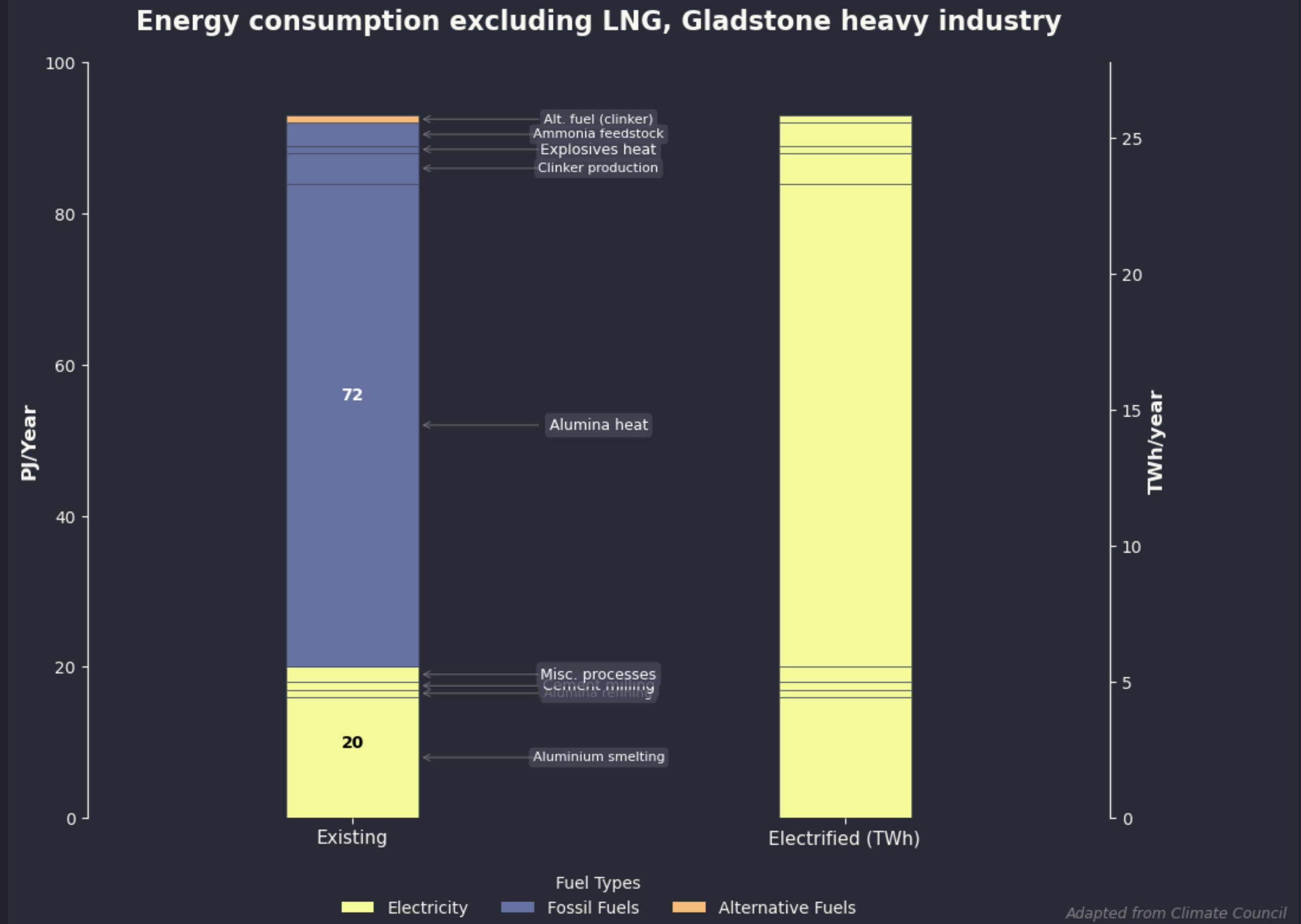

Even without looking at the gas fuelled liquefaction power plants on Curtis Island (consumption probably 25 PJ per year) Climateworks identified around 90 PJ of energy consumption in the Gladstone region from explosives, alumina refining, aluminium smelting, cement manufacture and other process. By far the biggest user of energy are the two alumina refineries majority owned by RIO.

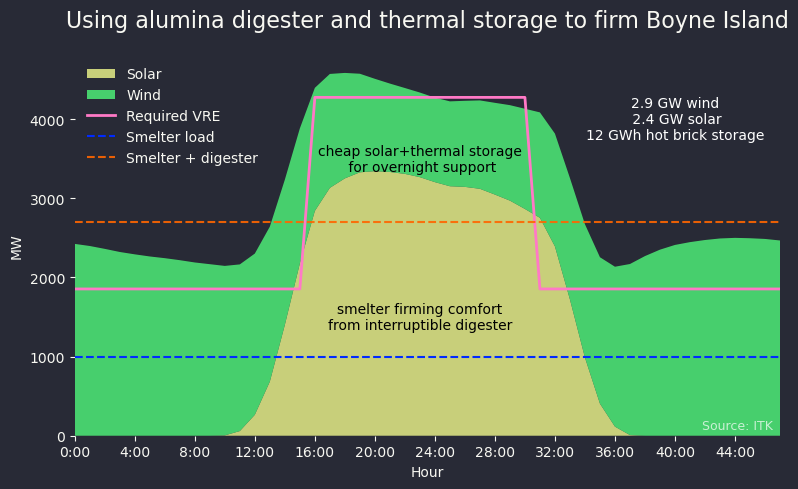

Ever since I first heard of the idea I have been excited by the concept of replacing the gas used to heat the alumina boilers with electricity, and over powering the boilers (digesters) so that excess heat is produced in the daytime. That heat is stored as thermal storage and when the sun goes down the thermal storage is released to keep the alumina digesters running.

Electrifying the refineries has two key advantages of which one is pretty much unique to Gladstone. The first advantage of electrifying the refinery is the gas that is freed up. About 2/3 of the gas consumed at the refinery is consumed by the digesters and if the digesters were electrified maybe as much as 40 PJ a year of gas would be freed up.

The second and unique advantage is that alumina digesters, being at one level, tubs boiling bauxite impurities off can be turned up or down. They are basically and not without some cost, interruptible.

On the other hand aluminium smelters have traditionally been designed not to be interrupted. The Boyne Island smelter also owned by RIO wants to operate flat out every hour of the year. If power is interrupted for more than a couple of hours the alumina/aluminium in the pot solidifies and the pot has to be thrown away. That’s very, very expensive and basically closes the smelter for a year or so. And so operating an aluminium smelter on wind and solar from a stand alone perspective can’t be done unless there is a source of firming power available at all times.

It turns out that if you electrify the alumina digesters they require just about twice as much electricity as the smelter. But as mentioned the digesters are interruptible. This means that in a wind and solar drought if you turn off the digesters there is still enough power left for almost every half hour of every year to keep the smelter going. And a relative low duration battery takes care of the rest.

Basically then if you ran the boilers on thermal energy supplemented with low cost thermal storage you wouldn’t really need any firming for the smelter. There would still be a firming cost in the form of lost alumina production but if you compare that cost to say allocating a big portion of Borumba pumped hydro project to providing aluminium firming I reckon the refinery electrification is the winner.

Doing all that though requires lots of wind and solar. The refinery digesters and the aluminium smelter between them need about 16 TWh of electricity per year (about 8% of current Australian demand). If you go with a 50:50 wind and solar mix, more solar because its used to provide the thermal storage, it’s something like 4 GW of solar and 3 GW of wind maybe $15bn of investment.

But there’s no transition without transmission

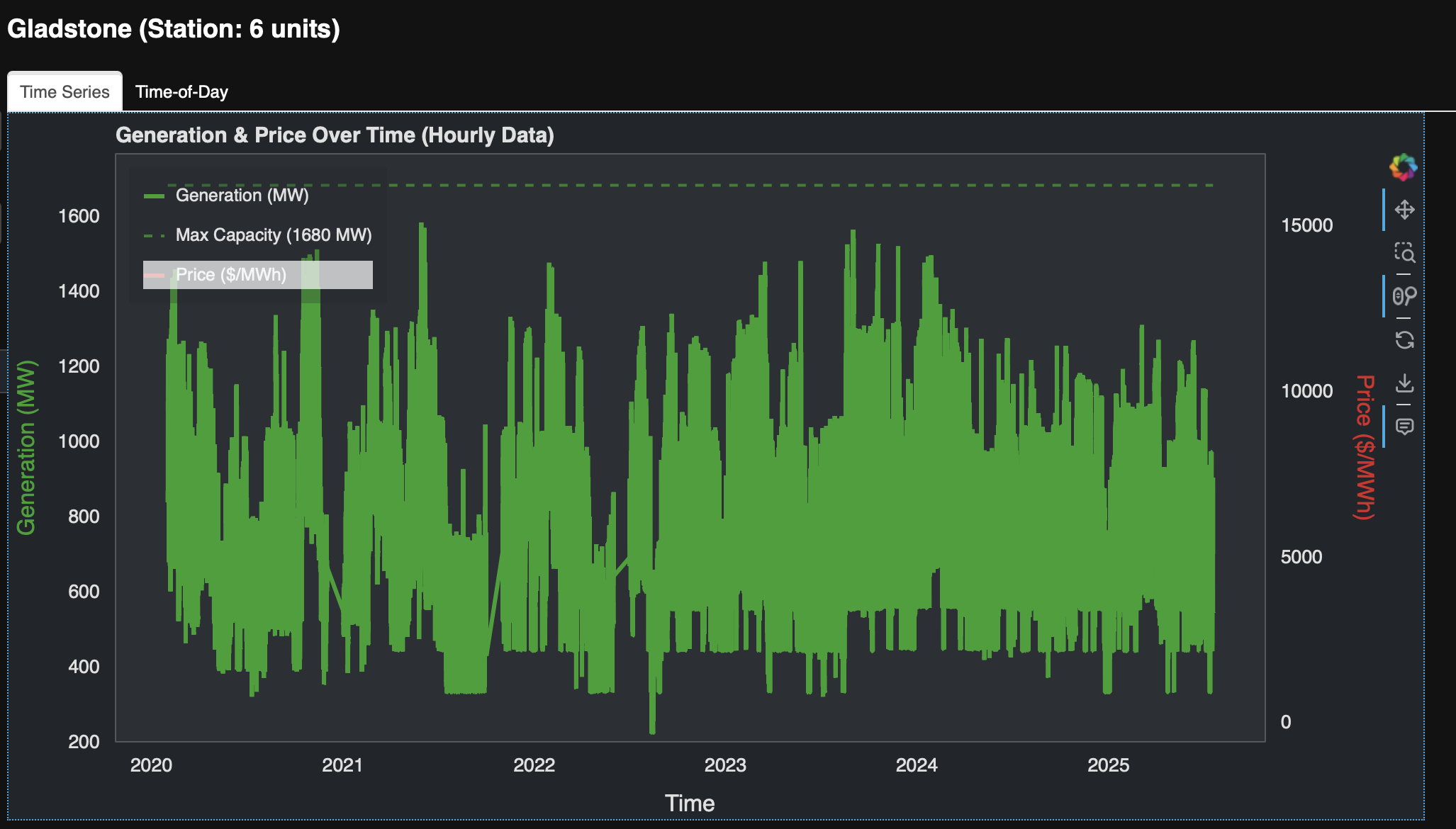

Right now the electricity used in Gladstone is mostly sourced from the Gladstone Power station. It rarely if ever operates at nominal capacity.

Coal is sourced mainly from Glencore’s Rolleseton mine and the station consumes about 4 mtpa. Gladstone Power Station’s owners are subsidised by CS Energy, a State Govt owned entity. CS Energy’s last 3 annual reports including FY24 show annual movements in the onerous contract provision of $107 m (FY22), $-17 m benefit(FY23) and $85 m cost(FY24). The subsidy expires somewhere in the 2028-2030 period which of course makes it a likely time for the station to close. Of course the QLD Govt could always continue subsidising it. Somehow there are no less than 5 separate owners of the Gladstone Power Station, Rio has 42% and NRG 37.5 and then there are three smaller shareholders. Humorous really as the owners can be guaranteed to have different ideas about what should be done and future capex if any. That’s the trouble with long term JVs, over time the interests of owners are bound to diverge from the original, some owners will fade some will grow.

When the station does close if it isn’t repurposed there will be a clean up liability. However because there is no attached coal mine it probably wont be that significant in the bigger scheme of things.

To summarise.

- Gladstone power station is at the end of its life and costs the QLD Govt owned CS Energy well in excess of $50 m per year.

- There is a very large but also difficult to win prize in replacing the gas at Rio’s majority owned alumina refineries in Gladstone. I personally doubt whether the current QLD Govt has sufficient clarity of purpose to even head in the right direction.

- The Boyne Island smelter needs firming if it is to run on renewable energy.

- If the firming is provided by Borumba it will be expensive, because Borumba will be expensive.

- In general the more aggregated the supply portfolio the cheaper the firming. That is firming all of QLD is cheaper measured relative to the delivered price of electricity across QLD than firming just Boyne Island. The simple reason for this is the portfolio effect, a big portfolio of demand and supply has lower variability than a small portfolio. This is true for the NEM as a whole and is why some degree of national planning is entirely appropriate no matter how many political arguments it causes and no matter how much self interest and noses out of joint have to be dealt with.

- Most importantly and the subject of this note, there is no transition without transmission. An absolutely vital no regrets decision , is to make certain there is enough transmission and generation elsewhere so that Gladstone Power Station can be closed.

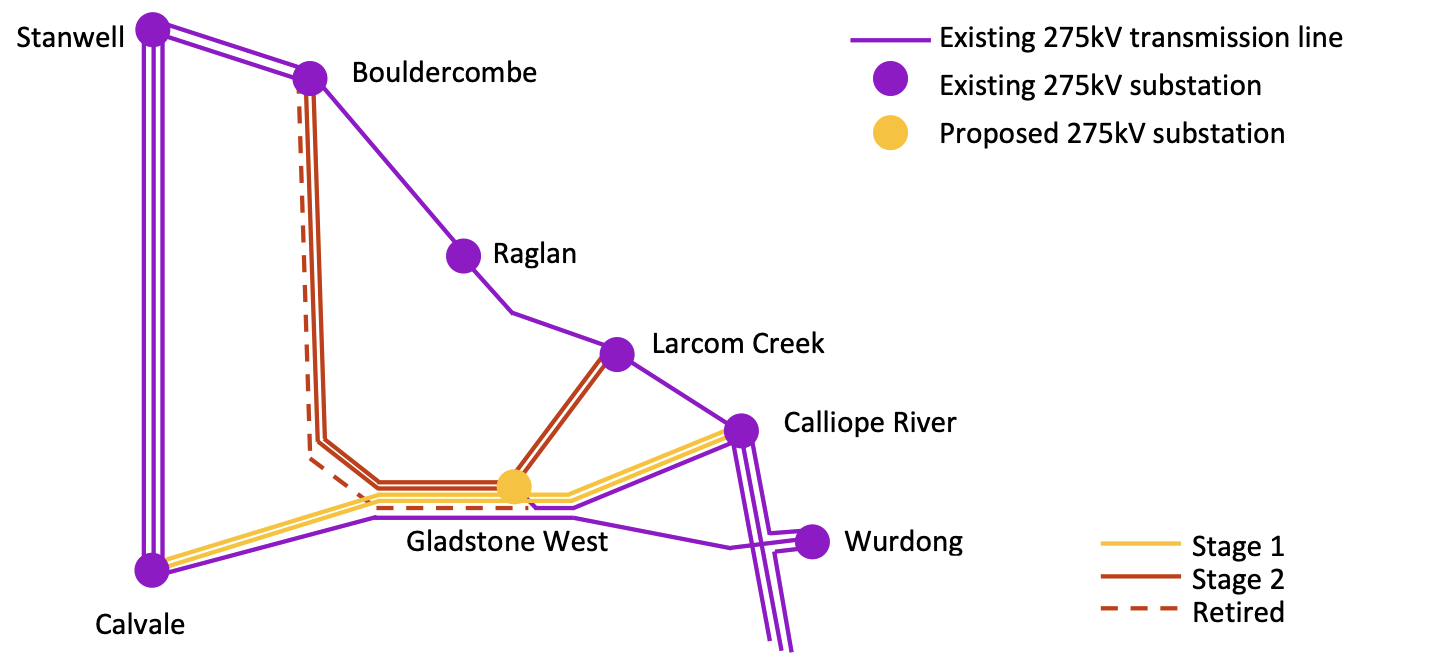

Powerlink’s Gladstone transmission plan

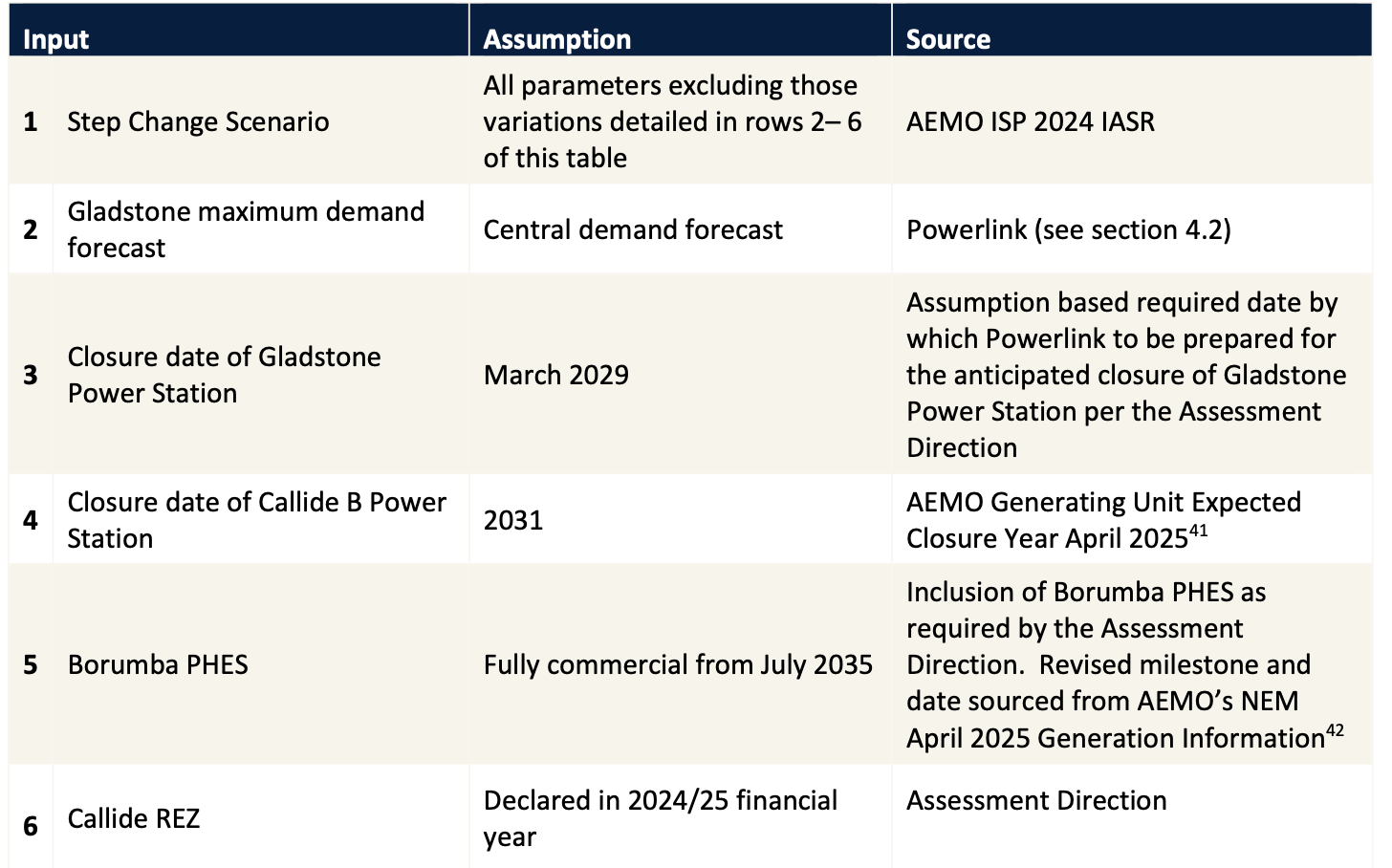

The assumptions underlying the plan are taken from the Powerlink document. Of course the QLD Government is not bound to follow the plan it can probably subsidise Gladstone Power Station for 20 years if it wants to. Rio has a new CEO who may have different priorities to the prior CEO. Even RIO shareholders who broadly want the company to achieve its stated decarbonisation goals may change their priorities. So assumptions in the plan are just that, assumptions. They look sensible though.

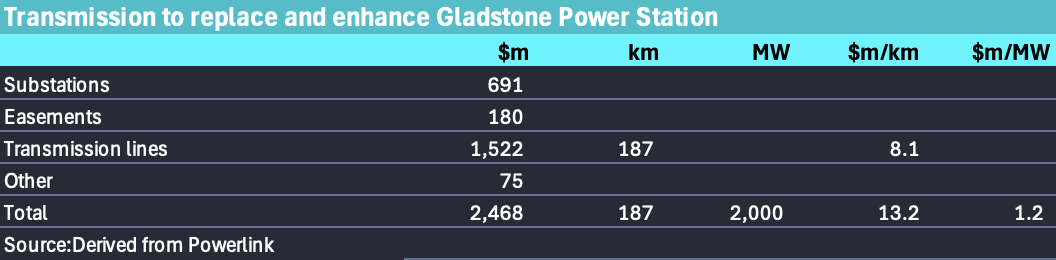

A summary of the plan is shown below

And after reorganising the data provided by Powerlink I came up with the following cost summary.

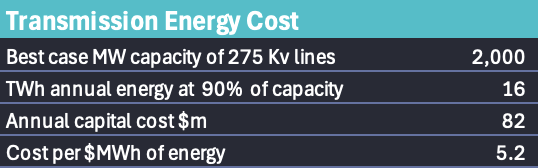

And if you assume a 30 year life, ignore minimal operating costs and don’t think about NPV analysis you can get to $5.20 a MWh. Does assume best case carrying capacity of 275 KV lines using modern conductors etc.

ITK comment

2 GW is not even in the ball park if RIO, in cooperation with the State and Federal Govts did decide to electrify the refineries. You need more like 5-6 GW of transmission to do that. Sadly pumped hydro, a concept people understand with the magic words “long duration” is always likely to get selected over thermal storage. Thermal storage basically means hot bricks. The process heat for alumina is not that high. Alumina digesters require 150C to 300C. The heat would be provided by resistive heating and a medium such as Rondo Bricks can provide 1000 C back to a process so easily manages an alumina digester.

In the alternative Boyne Island smelter requires lots of firming. Because the aluminium smelter can’t manage more than a couple of hours without full input power (the alumina/aluminium in the pot solidifies), then you have to have available firming power 100% of the time. Essentially that means reserving the firming power. It could come from gas generators, but more likely it’s a firm or firming supply agreement with your friendly gentailer.

In any case the point of this article was simply to note that Gladstone has unique possibilities for decarbonisation available nowhere else in Australia and despite lots of reports nothing much happens. Meantime Gladstone closure gets closer and so Queenslanders, if they are lucky will in fact get some just in time transmission.